3D modeling continues to add value to different industries and customers, as companies try to catalog assets or the environment around them, recreate or replace antiquated drawings, and/or develop interactive models that help drive more efficient maintenance and operation. The use of smart 3D models in the energy and utility industry has created an innovative way to manage aging plants by providing updated smart views of assets with accuracy down to the millimeter (mm) level.

These smart plans can be the basis for plant operations and provide another level of guidance for maintenance, ordering parts, or updating assets within the plant. In the past, creating immersive smart 3D models of legacy plants required exhaustive manual surveying and then converting the information to achieve a truly impactful, usable model. Today, with the advancement of surveying technology, such as laser scans using point cloud data, and an engineering model services provider like Avineon, creating Smart 3D Models has become really easy.

"Smart" Plans to Audit and Maintain Legacy Assets

With Smart 3D Models, plant owners enhance overall plant operations in two significant ways. With millimeter (mm) level precision, Smart 3D Models provide a more efficient planning tool for modifications and operational changes across a power plant.In addition, accessibility of Smart 3D Models is not limited to those with access to paper plans or antiquated software. This allows models to be accessible even on workstations across the plant workforce.

With Smart 3D Models, plant owners enhance overall plant operations in two significant ways. With millimeter (mm) level precision, Smart 3D Models provide a more efficient planning tool for modifications and operational changes across a power plant.In addition, accessibility of Smart 3D Models is not limited to those with access to paper plans or antiquated software. This allows models to be accessible even on workstations across the plant workforce.

In order to capture data using the laser scanned point cloud technique, benchmarks are first created on the local coordinate system of the plant. These benchmarks then become the landmarks of the plan as they are usually fixed, accessible, and viewable. Next, the plant is broken into parts with specific High Definition Survey (HDS) targets that require detailed surveying (i.e. turbine, reactor, cooling tower). Based on the specific measurements taken from the HDS target and the identified benchmarks, a laser scan creates a point cloud reflection of the HDS target.

Point Cloud Data after a Laser Scan

360-degree panoramic photographs are also taken of the HDS target, which is linked to the smart plot plan. Rather than additional manual measuring and surveying as needed with more expensive and archaic surveying techniques, the laser scan and subsequent point cloud data diagrams are thoroughly analyzed digitally for accuracy.

360-degree panoramic photographs are also taken of the HDS target, which is linked to the smart plot plan. Rather than additional manual measuring and surveying as needed with more expensive and archaic surveying techniques, the laser scan and subsequent point cloud data diagrams are thoroughly analyzed digitally for accuracy.

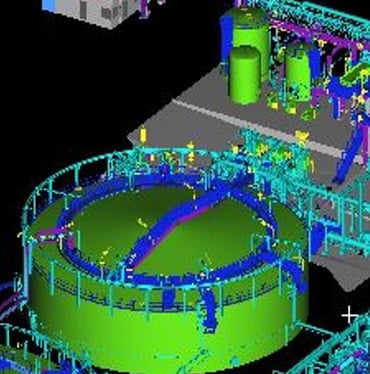

In the post scan analysis, a registration process is implemented once the HDS target point cloud data is received. The registration process is a method of aligning various point cloud data plans into one cohesive coordinate system. An expert partner like Avineon helps you in converting the point cloud plans with HDS software into geometric models. Measurements are made directly into the 360-degree panoramic views with software like TruView. Integrating the appropriate intelligence in 3D CAD Plant Design Applications with data from piping and instrumentation diagrams (P&IDs), a complete Smart 3D Model of the plant is generated.

Primitive R3D Model

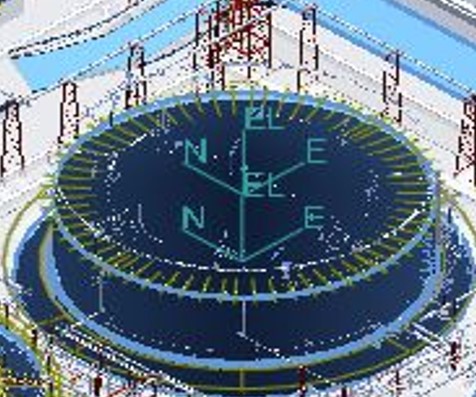

Lastly, with 3D reviews and clash detection, a final “Smart” 3D model is rendered, which incorporates all aspects of the asset or assets of the plant in one immersive system. This process can also be tailored with a specific 3D model software of preference.

Final "Smart" 3D Plan

Many global utility companies have benefited from the laser scanned point cloud data and our 3D modeling experience. With immersive dimensional views and millimeter level accuracy, plant owners can proactively audit and manage aging assets. Overall, as a cost effective solution, Smart 3D Models can improve safety with better accessibility and more informed plans, improve maintenance across the plant and reduce the complexity and cost of extensions or modifications to plants in the future.